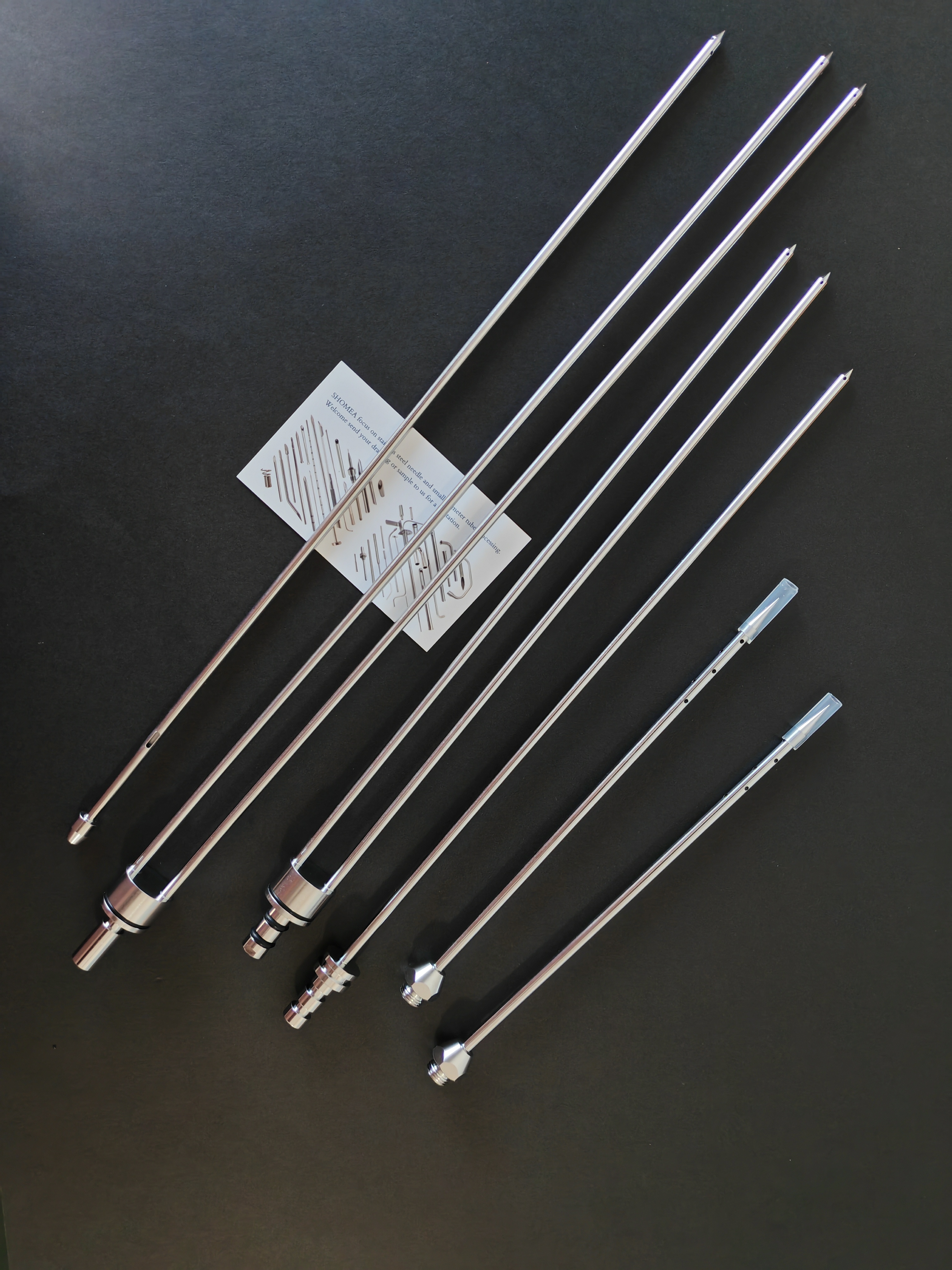

316L Food-Grade Saline Injection Needles: The Essential Tool for Enhancing Meat Product Quality and Production Efficiency

Subtitle: In the meat processing industry, 316L stainless steel saline injection needles have become the preferred choice for modern food processing enterprises due to their excellent corrosion resistance and food safety compliance.

[Shenzhen, China] - [Current Date] - In the meat processing industry, saline injection technology has become a critical process for improving product quality, enhancing texture, and extending shelf life. As the core component of this technology, the material selection for saline injection needles directly impacts processing efficiency, product safety, and equipment lifespan. 316L stainless steel has become the material of choice for high-end food-grade saline injection needles due to its unique performance advantages.

Core Advantages of 316L Food-Grade Saline Injection Needles

1. Excellent Corrosion Resistance for High-Salt Environments

Saline solutions used in meat processing contain high concentrations of sodium chloride, which is highly corrosive to metal materials. 316L stainless steel contains 2-3% molybdenum, giving it superior corrosion resistance in chloride environments. Compared to ordinary stainless steel, 316L effectively resists corrosion from saline, seasonings, acidic substances, and other corrosive media, ensuring the injection needle maintains stable performance during long-term use and preventing needle clogging or breakage due to corrosion.

2. Compliance with Food-Grade Safety Standards

316L stainless steel meets food-grade material standards (such as GB 9684, FDA, NSF, etc.), containing no heavy metal elements harmful to human health and preventing the migration of harmful substances into food. During meat processing, the injection needle directly contacts food ingredients, and the food safety of 316L stainless steel ensures the final product's hygiene and safety, meeting strict food hygiene regulations.

3. Ultra-Low Carbon Design to Prevent Intergranular Corrosion

The "L" in 316L stands for low carbon (carbon content ≤0.03%), a characteristic that prevents carbide precipitation during welding, avoiding intergranular corrosion issues. For injection needle structures requiring precision welding, 316L stainless steel maintains corrosion resistance in the weld zone, extending equipment lifespan and reducing maintenance costs.

4. Excellent Mechanical Properties for High-Pressure Injection

316L stainless steel possesses outstanding strength and toughness, with tensile strength reaching 485-620MPa and yield strength ≥170MPa. These mechanical properties enable it to withstand high-pressure injection forces while maintaining thin-wall needle tube design, ensuring uniform saline injection into meat products and improving product quality.

Why Choose 316L Over Other Materials?

Compared to 304 stainless steel, 316L has clear advantages in corrosion resistance. While 304 stainless steel is more cost-effective, its corrosion resistance is inferior in high-salt, high-humidity food processing environments, making it prone to corrosion and rust issues over time, which can affect product hygiene and safety. The molybdenum content in 316L stainless steel gives it stronger corrosion resistance in acidic, alkaline, and chloride-containing environments, making it particularly suitable for long-term use in meat processing settings.

Application Areas

316L saline injection needles are widely used in:

Pork Product Processing: For saline injection in ham, bacon, sausage, etc., to improve texture and water retention

Poultry Processing: For seasoning injection in chicken, duck, etc., to enhance flavor

Beef Products: For tenderizing treatments in steak, beef rolls, etc.

Seafood Processing: For seasoning and water retention in fish paste, fish balls, etc.

Quality Certification and Standards

Food-grade 316L stainless steel must comply with international standards such as GB 9684 "National Food Safety Standard for Stainless Steel Products," FDA 21 CFR 175.300, NSF/ANSI 51, etc., ensuring the material's chemical composition, mechanical properties, and food safety meet food processing application requirements. Manufacturers must provide complete material certificates and food safety test reports to ensure product safety and reliability.

Conclusion

Choosing 316L food-grade saline injection needles is not just selecting a material, but choosing an efficient, safe, and reliable food processing solution. With its exceptional comprehensive performance, 316L stainless steel provides food processing enterprises with trustworthy tools, helping to improve product quality, enhance production efficiency, and reduce equipment maintenance costs. In the meat processing field, 316L stainless steel has become synonymous with high-quality saline injection needles.