Mastering Materials for Perfect Transplants: How to Choose the Best Material for FUE Punches

Subtitle: Material selection directly impacts the success of FUE surgery and follicular survival rate. Shomea provides an in-depth analysis of the core considerations.

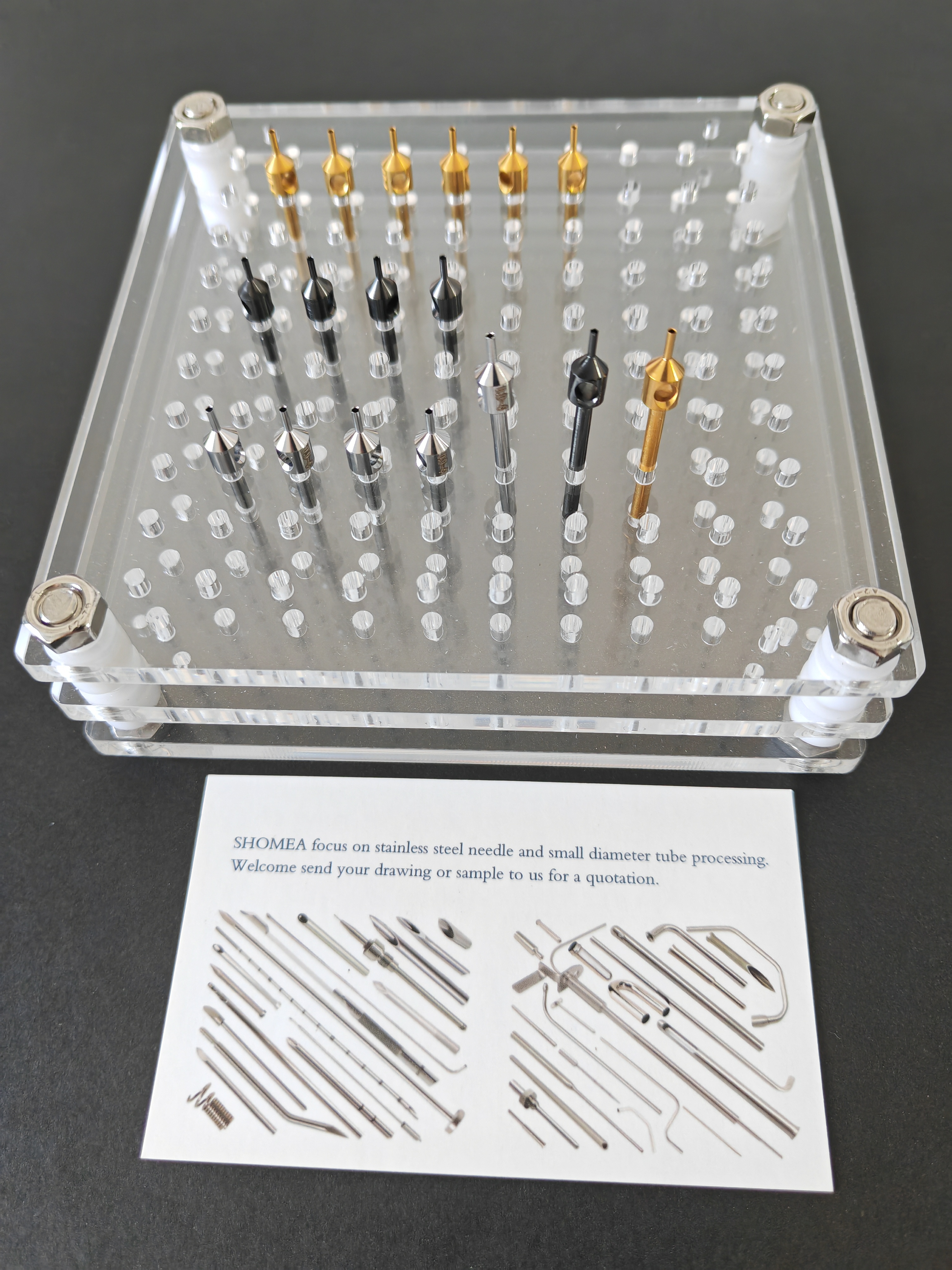

[Shenzhen, China] - [Current Date] - In the field of hair transplantation, Follicular Unit Excision (FUE) has become the mainstream technique. The performance of the core instrument in FUE procedures—the FUE Punch—largely determines the precision, efficiency, and trauma to the follicular units. Industry experts emphasize that the cornerstone of a punch's performance lies fundamentally in the selection of its manufacturing material. As a specialized manufacturer of precision medical device components with over 20 years of experience, Shenzhen Shomea Hardware Products Co., Ltd. understands the critical importance of materials science and shares key considerations for selecting materials for FUE punches.

1. Superior Hardness and Wear Resistance: The Guarantee of Surgical Sharpness

An FUE punch must penetrate the tough scalp epidermis, requiring the material to possess extremely high hardness and wear resistance. Premium surgical-grade stainless steel (such as 440C or 304/316L medical stainless steel) is the preferred choice. High hardness guarantees that the punch tip remains exceptionally sharp throughout lengthy procedures, minimizing wear from repeated use. A dull tip increases compression and trauma to the surrounding tissue, adversely affecting graft harvest. Shomea utilizes refined medical stainless steel, processed through advanced heat treatment, to ensure every punch maintains a lasting, razor-sharp edge.

2. Unparalleled Biocompatibility: The Primary Line of Safety

As an invasive medical device, biocompatibility is a non-negotiable baseline. Materials must comply with international standards like ISO 10993, ensuring they are non-toxic, non-irritating, and non-sensitizing to human tissue. Medical stainless steel, known for its excellent biocompatibility and corrosion resistance, can withstand repeated high-pressure, high-temperature sterilization without performance degradation, eliminating infection risks related to material failure. All materials used by Shomea come with complete material certificates and biocompatibility test reports, ensuring safety for global clinics and patients.

3. Precision Machinability: Achieving Ultra-Thin Walls and Sharp Edges

Excellent materials must be paired with top-tier manufacturing processes. FUE punches strive for minimal diameters and ultra-thin walls to reduce incision size. This demands materials with excellent machinability, allowing them to be precision-machined by CNC equipment into burr-free, uniform tips. Any microscopic imperfection can potentially lead to transection or damage of the follicular unit during extraction. Leveraging advanced CNC technology and stringent quality control, Shomea ensures its punches feature mirror-smooth inner walls and consistently sharp edges, maximizing the intact follicular unit extraction rate.

4. Surface Finish and Coating Technology: Reducing Friction for Smooth Penetration

To reduce resistance during skin penetration, high-end punches often employ special surface treatments (such as Parylene coating) or high-gloss polishing. A smooth surface not only minimizes tissue adhesion for smoother operation but also further enhances corrosion resistance. The manufacturer's capability in surface treatment processes is a key factor to consider.

A spokesperson for Shomea commented: "Choosing an FUE punch is essentially about selecting the underlying materials science and manufacturing craftsmanship. This tiny tube carries the patient's hope for restored confidence. At Shomea, starting from every coil of stainless steel raw material, we integrate the principles of 'precision, safety, and reliability' into the entire manufacturing process. We are committed to providing global hair transplant surgeons with exceptional tools that feel like a natural extension of their surgical skill."

About Shenzhen Shomea Hardware Products Co., Ltd.:

Established in 2002, Shenzhen Shomea Hardware Products Co., Ltd. has been dedicated to the R&D and manufacturing of precision stainless steel needles, tubes, and components. With a modern production base covering over 6,500 square meters and equipped with advanced CNC machines and tube cutting equipment, Shomea's products are widely used in demanding fields such as medical and aesthetic instruments. Renowned for superior quality, consistent performance, and professional customisation services, Shomea has become a reliable partner for numerous renowned enterprises worldwide.