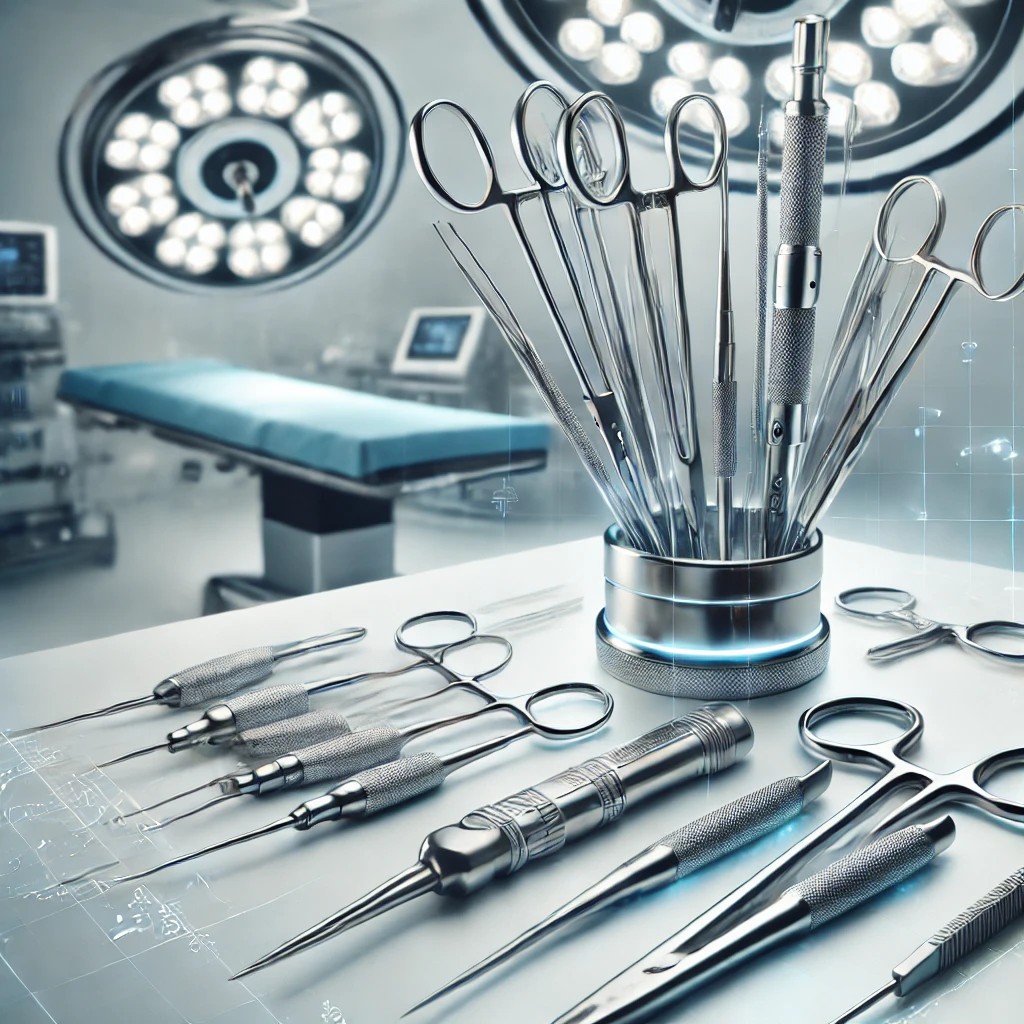

Minimally invasive surgery (MIS) has rapidly become the preferred approach in modern medicine, offering reduced incisions, lower infection risks, and faster recovery times. At the heart of this evolution lies custom medical components, which are revolutionizing the field by driving innovation and enhancing outcomes.

Key Features of Minimally Invasive Surgery

MIS relies on precision-engineered instruments with the following critical characteristics:

Compact and Precise Design: Instruments must operate in tight spaces without compromising surrounding tissues or organs.

Biocompatible Materials: Tools must ensure compatibility with the human body to avoid inflammation or adverse reactions.

Strength and Flexibility: Instruments need to withstand multidirectional forces while maintaining the flexibility to navigate complex anatomical structures.

Advantages of Custom Components

Compared to standard instruments, custom components offer unique benefits for MIS:

Tailored to Specific Needs

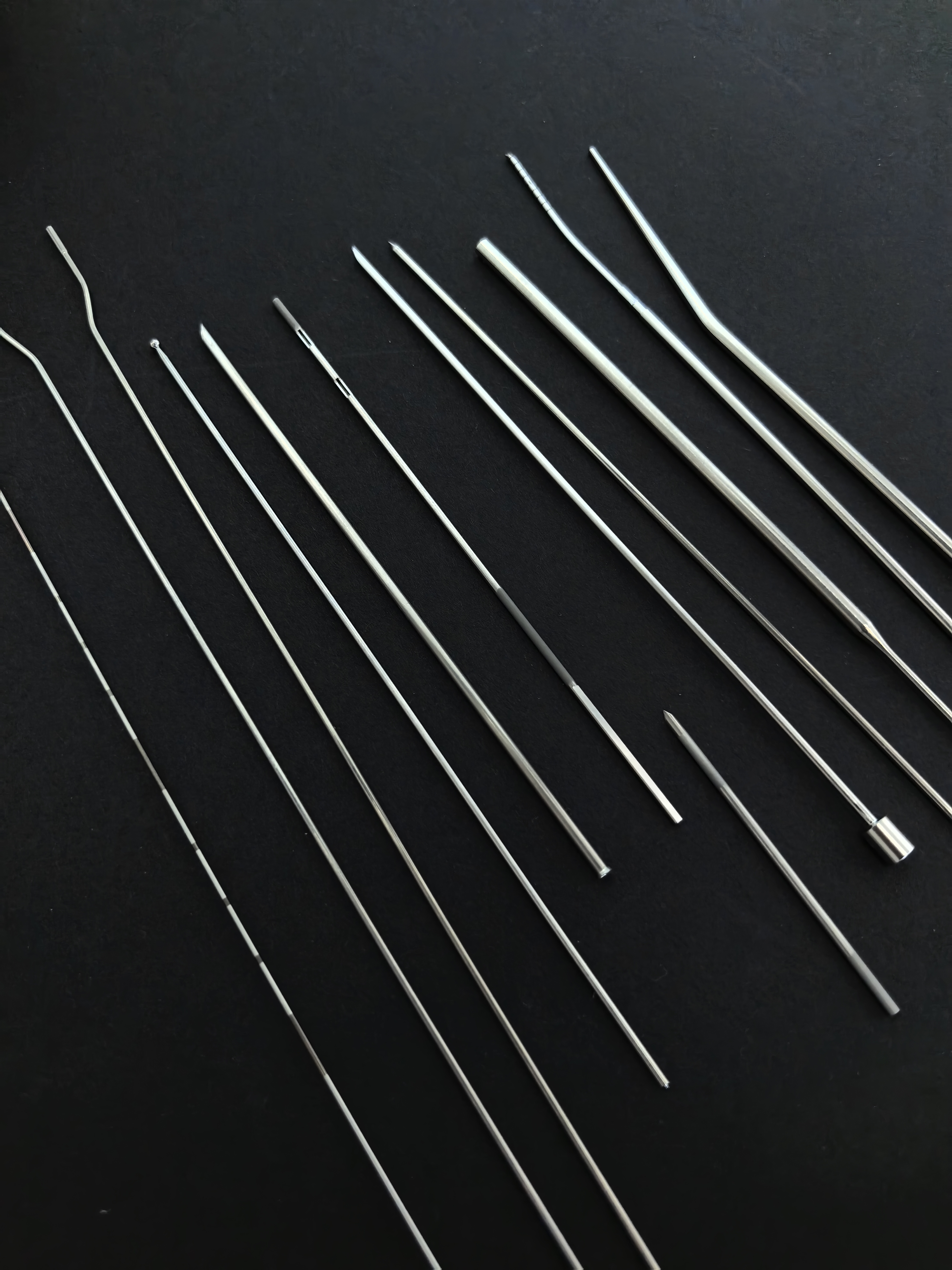

Custom components can be designed to meet the requirements of specific procedures, such as tailored lengths, angles, or diameters for surgical needles, forceps, or catheters.Enhanced Surgical Precision

Precision-engineered components provide surgeons with greater control, improving surgical accuracy and success rates.Improved Patient Recovery

Instruments designed for individual needs minimize tissue trauma, leading to less postoperative discomfort and quicker recovery.

Integration of Innovative Technologies and Materials

Advances in technology are further enhancing the development of custom components:

Additive Manufacturing (3D Printing)

This technology allows for rapid prototyping and production of highly complex and individualized components.High-Performance Medical Materials

Materials such as 316L stainless steel, titanium alloys, and other high-strength metals ensure biocompatibility and durability.Surface Treatment Technologies

Advanced coatings reduce friction during procedures, improving instrument maneuverability and efficiency.

Future Directions

As technology advances, the role of custom components in MIS will continue to expand. Key trends include:

Higher Precision Design and Manufacturing

AI and precision machining will lead to more individualized designs with near-zero manufacturing errors.Multi-Functional Instruments

Custom components will increasingly combine multiple functions, such as cutting, suturing, and cauterization, into a single tool.Sustainable Materials

Biodegradable and sustainable materials may replace traditional metals, reducing long-term impacts on the body.

The future of minimally invasive surgery is inseparable from the innovations driven by custom medical components. By addressing individual needs and enhancing surgical efficiency, custom components empower surgeons and improve patient outcomes. This trend represents a transformative era in the medical device industry, driving new possibilities for MIS and beyond.