Minimally invasive medical technology, as an important trend in modern medicine, allows for treatment through the smallest incisions, significantly reducing surgical risks and shortening recovery times. Achieving this goal relies heavily on precision processing technology in medical devices, particularly in the development and manufacturing of ultra-thin wall needles. Ultra-thin wall needles are key components in minimally invasive surgeries, and the precision of their manufacturing process directly impacts the surgical outcome and patient comfort.

1. Definition and Importance of Ultra-Thin Wall Needles

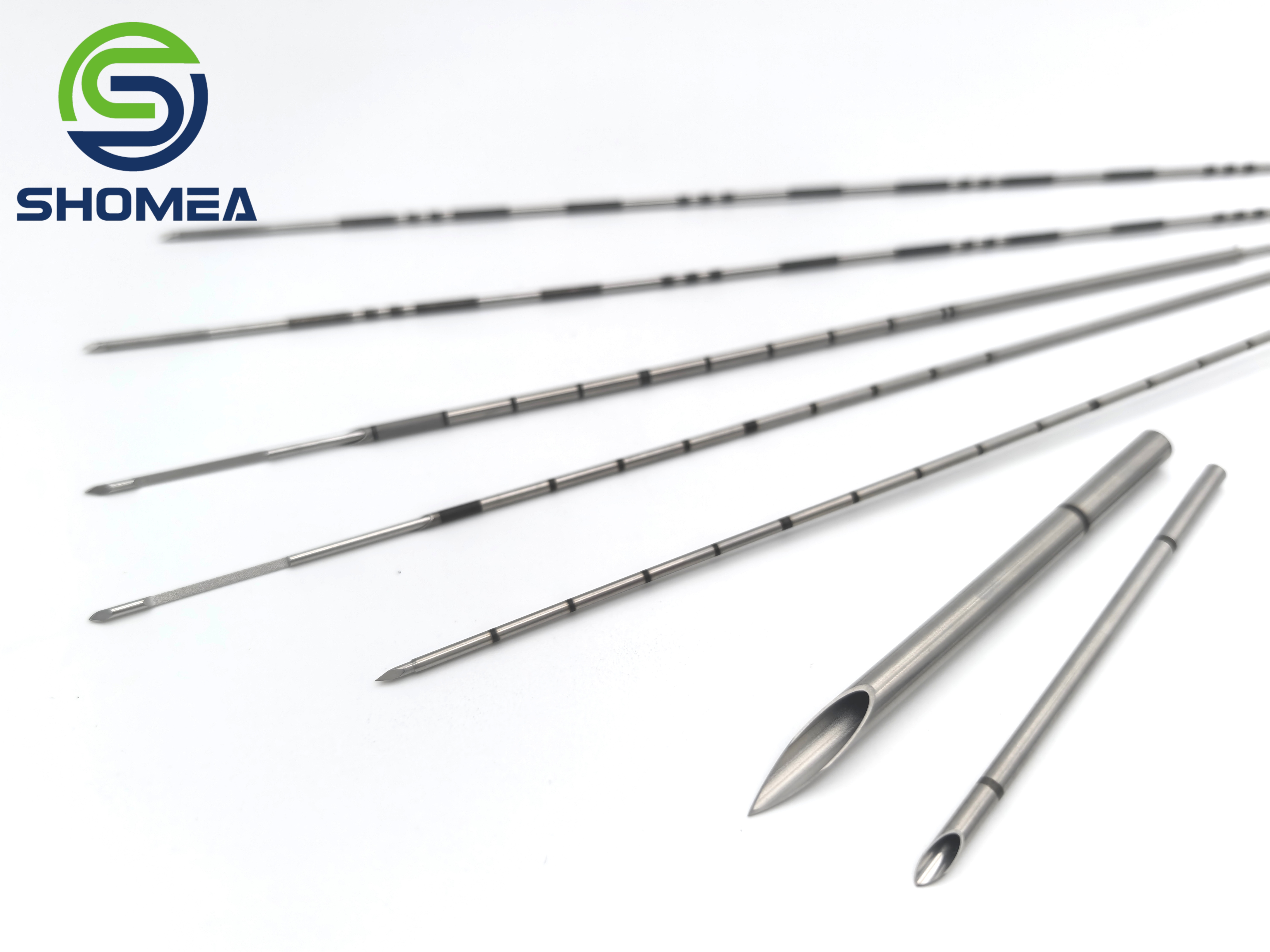

Ultra-thin wall needles are characterized by very thin walls and a ratio of inner to outer diameter close to 1:1. They are commonly used in medical situations that require fine and precise operations.

High Precision Requirements:

The wall thickness of ultra-thin wall needles can be as thin as 0.1mm or even thinner, requiring meticulous control over every detail during manufacturing to ensure high precision and stability.

Clinical Significance:

- Reducing Patient Discomfort: The ultra-thin wall design results in smaller puncture wounds, reducing tissue damage and the occurrence of post-operative complications.

- Enhanced Operational Flexibility: The smaller diameter of the needle allows better access to complex or narrow anatomical structures, increasing surgical flexibility and accuracy.

Faster Recovery: Because the puncture wound is smaller, patients recover faster, have shorter hospital stays, and experience significantly less pain.

2. Precision Processing Technology for Ultra-Thin Wall Needles

Manufacturing ultra-thin wall needles involves advanced material selection and the support of various high-precision processing techniques.

Material Selection:

- Stainless Steel (e.g., 304 or 316L): This material offers strong corrosion resistance and good biocompatibility, making it ideal for medical device production.

Nickel-Titanium Alloy (Nitinol): Due to its shape-memory properties and flexibility, it is particularly suited for making needles that need to bend or stretch, commonly used in complex surgical pathways.

Processing Techniques:

- Laser Cutting: Laser cutting technology allows for precise cutting of very thin materials, handling complex shapes while minimizing excess heat, thus maintaining the integrity of the material.

- Precision Stretching: This process involves gradually stretching metal tubing to uniformly reduce the wall thickness while ensuring precise control of both inner and outer diameters.

Electrochemical Machining (ECM): A non-contact method that uses electrochemical reactions to remove metal, enabling precise processing, especially suitable for making extremely thin-walled tubes.

Quality Control:

To ensure the accuracy of ultra-thin wall needles, strict quality control measures are implemented during production. Common testing methods include:

- Microscopic Measurement: Using a microscope to examine the cross-section of the needle to measure wall thickness and detect any internal defects.

Non-Destructive Testing (NDT): Techniques such as X-ray or ultrasound are used to detect cracks or structural issues inside the needle.

3. Application Areas of Ultra-Thin Wall Needles

Ultra-thin wall needles, with their excellent performance, are widely used in several medical fields, particularly in minimally invasive surgeries.

Minimally Invasive Surgery:

- Blood Vessel Puncture: Ultra-thin wall needles are used for blood vessel puncture in procedures like catheter insertion, blood sampling, and biopsy, minimizing surgical trauma.

Endoscopic Surgery: In gastrointestinal endoscopy, joint arthroscopy, and other types of endoscopic surgeries, ultra-thin wall needles not only pass through narrow passages smoothly but also provide better visibility during surgery.

Drug Delivery and Injections:

Ultra-thin wall needles are commonly used in drug delivery systems, such as insulin injections and vaccine administration. In these applications, ultra-thin needles ensure precise control over the rate and amount of drug delivery, preventing over-injection or damage to surrounding tissues.

Diagnostic Equipment:

Ultra-thin wall needles are also used for blood sampling, tissue biopsies, and other diagnostic procedures, ensuring the integrity of the samples and minimizing patient discomfort.

- Biopsy: Ultra-thin wall needles can be used for biopsies in various parts of the body, ensuring smaller incisions and faster recovery.

Neurointervention: In neurointervention procedures, the fine design of ultra-thin wall needles helps to reduce damage to surrounding nerves.

4. Future Development Trends

As technology advances and the demand for minimally invasive surgeries increases, the manufacturing techniques for ultra-thin wall needles will continue to improve in terms of precision and cost-effectiveness.

Material Innovation:

In the future, more advanced alloy materials such as titanium alloys and nickel-titanium shape memory alloys may be used, providing better flexibility and strength.

Smart Technology:

With advancements in sensor technology, ultra-thin wall needles may integrate additional smart functions, such as temperature, pressure, or position monitoring systems.

Personalized Customization:

Due to variations in patients' anatomical structures, the customization of ultra-thin wall needles will become more common, allowing for more precise medical solutions tailored to each individual patient's needs.

Ultra-thin wall needles, as key components in minimally invasive medicine, are becoming indispensable tools in surgeries due to the development of precision processing technology. They not only reduce patient discomfort but also improve the success rate and efficiency of surgeries. With the continuous progress in material science and processing technology, ultra-thin wall needles will become even more precise and safe, driving the future of minimally invasive medicine toward greater efficiency and personalization.